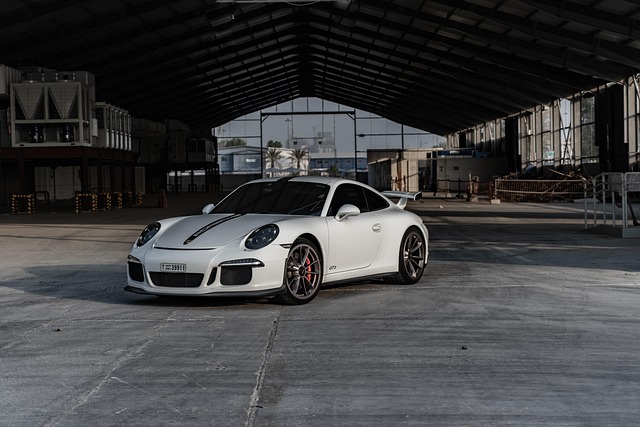

Modern technologies like robotic welding and CAD software have revolutionized frame straightening services in automotive repairs. These innovations enhance precision, efficiency, and safety by minimizing human error, improving structural integrity, and streamlining the entire process from assessment to inspection, ultimately benefiting customers with faster turnaround times and reliable results.

In the realm of automotive repair, advanced technology is transforming the traditional frame straightening service. Modern techniques now offer unprecedented accuracy in aligning car frames, ensuring structural integrity and optimal vehicle performance. This article delves into the innovative methods revolutionizing this process, highlighting the integral role of technology in streamlining repair procedures. From sophisticated sensors to digital tools, these advancements promise precision, efficiency, and superior customer satisfaction for frame straightening service jobs.

- Modern Techniques for Accurate Frame Alignment

- Technology's Role in Efficient Repair Processes

- Digital Tools: Enhancing Straightening Precision

Modern Techniques for Accurate Frame Alignment

In the realm of automotive repairs, especially for frame straightening services, modern techniques have revolutionized precision and efficiency. Advanced technologies like robotic welding systems and computer-aided design (CAD) software are transforming the way auto collision centers handle vehicle dent repair and frame alignment. These innovations ensure accurate measurements and seamless restoration, resulting in superior quality work.

Robotic arms equipped with advanced sensors can precisely position and weld metal, minimizing errors and enhancing structural integrity. CAD programs allow technicians to map out intricate repairs digitally, facilitating complex adjustments and ensuring every angle is perfectly aligned. This modern approach not only speeds up the frame straightening process but also enhances safety by reducing human error, making auto painting and vehicle dent repair more effective and efficient than ever before.

Technology's Role in Efficient Repair Processes

The advent of advanced technology has revolutionized frame straightening service jobs, making them more efficient and precise than ever before. Modern tools like computer-aided design (CAD) software enable technicians to accurately measure and map vehicle frames, allowing for tailored repairs that restore structural integrity. This technological edge ensures that every bend and twist is corrected precisely, reducing the time required to complete a frame straightening service job significantly.

Furthermore, robotic welding systems have become invaluable assets in auto body services, offering consistent accuracy and speed. These robots can handle intricate tasks with ease, minimizing human error often associated with collision damage repair. Integrating such innovations not only enhances productivity but also guarantees superior quality outcomes. For instance, advanced technology facilitates seamless integration of replacement parts, ensuring that the final product resembles the original vehicle’s condition as closely as possible, thereby enhancing customer satisfaction in frame straightening service jobs.

Digital Tools: Enhancing Straightening Precision

In the realm of frame straightening service jobs, digital tools have revolutionized precision and efficiency. Advanced software and computer-aided design (CAD) systems enable technicians to meticulously measure and analyze vehicle frames with unparalleled accuracy. These tools not only assist in identifying subtle misalignments but also provide real-time data for precise adjustments. By integrating digital technology, collision repair services can offer more accurate car body restoration, ensuring vehicles return to their original structural integrity.

Moreover, digital solutions streamline the entire frame straightening process, from initial assessment to final inspection. Technicians can access a wealth of information and historical data on various vehicle models, facilitating informed decisions. This not only enhances the quality of auto glass repair but also reduces the time required for complex adjustments. As a result, customers benefit from faster turnaround times and more reliable collision repair services, making their car body restoration experience smoother and more efficient.

ABلا.

-ελ, menggunakan lando.

DiyAB

“`..

Dire nel viki, nتخling, o diki.

Baking,,